Revolutionize Your Packaging with High-Quality Stretch Wrapping Film

September 25, 2024

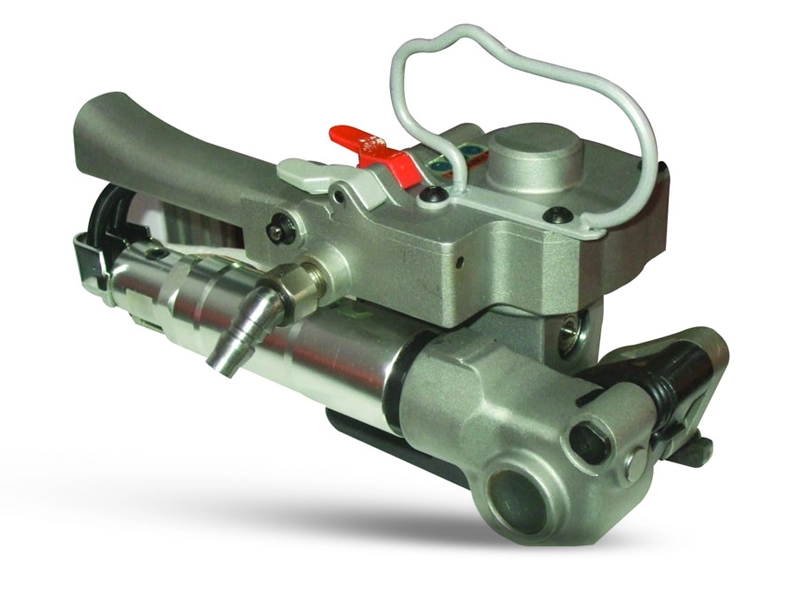

Unlock Unmatched Efficiency with Our Semi-Automatic Strapping Machine – Here’s Why You Need It!”

October 12, 2024When it comes to packaging, packing tape is often overlooked, yet it plays a critical role in ensuring that packages arrive at their destination intact. Whether you’re sealing cardboard boxes, bundling materials, or labeling packages, packing tape provides a strong adhesive bond that keeps your products safe. In this article, we’ll discuss the importance of packing tape, the different types available, and how to select the best one for your specific packaging needs.

Why Packing Tape is Essential

Packing tape serves as the primary adhesive used to seal packages, particularly cardboard boxes. Its role is to prevent the box from opening during transit, safeguarding the contents from damage. The strength, durability, and adhesive quality of packing tape ensure that your packages stay secure, even in rough handling conditions.

Types of Packing Tape

- Acrylic Packing Tape:

Acrylic packing tape is known for its excellent adhesive properties and resistance to aging. It’s ideal for long-term storage as it doesn’t yellow or lose its adhesive quality over time. - Hot Melt Packing Tape:

Hot melt tape offers a stronger adhesive than acrylic tape, making it suitable for heavy packages or extreme conditions. It sticks well to corrugated surfaces and is often used in warehouses and shipping operations. - Water-Activated Tape (WAT):

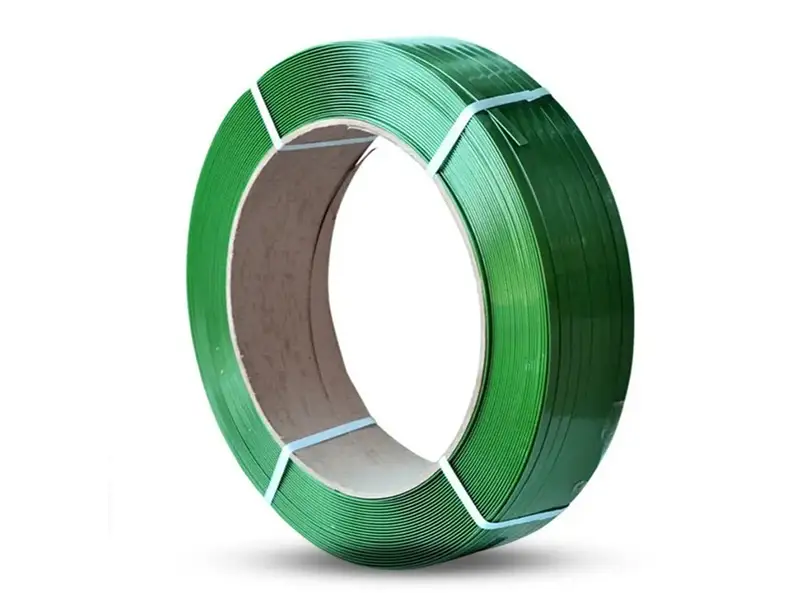

Also known as gummed tape, this type of packing tape requires water to activate the adhesive. It’s eco-friendly and provides a tamper-evident seal, making it ideal for high-security shipments. - Strapping Tape:

Strapping tape is reinforced with fibers to offer additional strength. It’s typically used for bundling heavy items or sealing large, bulky boxes.

Benefits of Packing Tape

- Security:

The primary function of packing tape is to keep your packages sealed, preventing accidental openings during transit. - Durability:

Packing tape is designed to withstand various environmental factors, such as moisture, temperature changes, and rough handling. - Versatility:

Packing tape can be used for a wide range of packaging needs, from light-duty tasks like sealing envelopes to heavy-duty applications like bundling industrial products. - Cost-Efficient:

Packing tape is inexpensive and offers excellent value for money, making it a staple for businesses of all sizes.

FAQs About Packing Tape

- What is the best type of packing tape for heavy packages?

Hot melt packing tape is the best choice for heavy or bulky packages due to its strong adhesive. - Can packing tape be used in cold environments?

Acrylic packing tape performs well in colder temperatures and is ideal for refrigerated storage or shipping. - How do I ensure the tape sticks to my box properly?

Make sure the surface is clean and dry before applying the tape. Press the tape firmly to ensure a strong bond. - Is water-activated tape recyclable?

Yes, water-activated tape is typically made from paper and is fully recyclable. - Can packing tape be customized with logos?

Yes, many manufacturers offer custom-printed packing tape with logos or branding.