Packing Tape: A Comprehensive Guide for Seamless Packaging

January 27, 2024

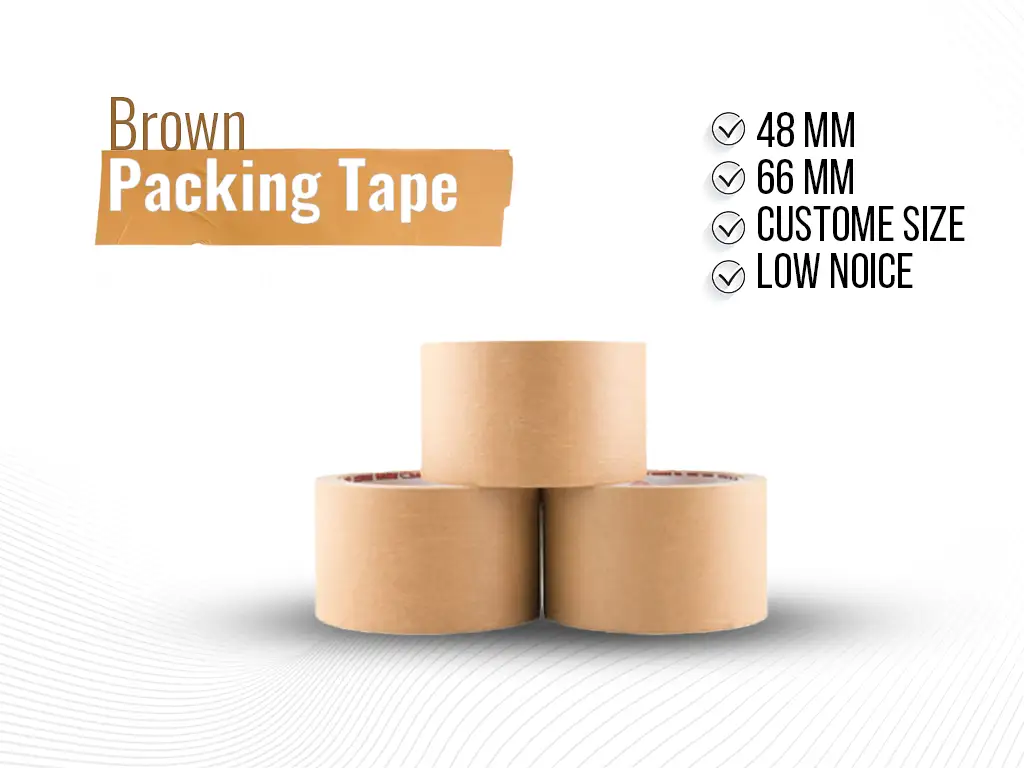

The Unsung Hero of Packaging: Exploring the Benefits of Brown Tape

March 7, 2024Dive into the world of PP strap manufacturing for carton packing. This comprehensive guide explores the intricacies of the process, the versatility of polypropylene, the eco-friendly aspects, and the crucial role these straps play in securing and enhancing the efficiency of carton packaging. Discover the precision behind the manufacturing of PP straps that elevate the standards of carton packing.

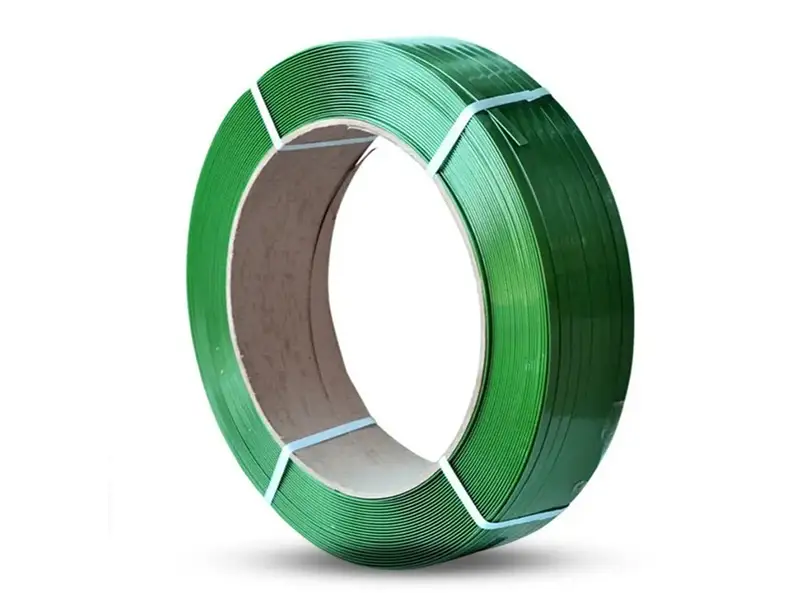

In the realm of carton packaging, the manufacturing of Polypropylene (PP) straps emerges as a vital element, blending both art and science. This article serves as your comprehensive guide to the intricate world of PP strap manufacturing, delving into the process, the versatility of polypropylene, the eco-friendly aspects, and the indispensable role these straps play in securing and optimizing carton packaging efficiency.

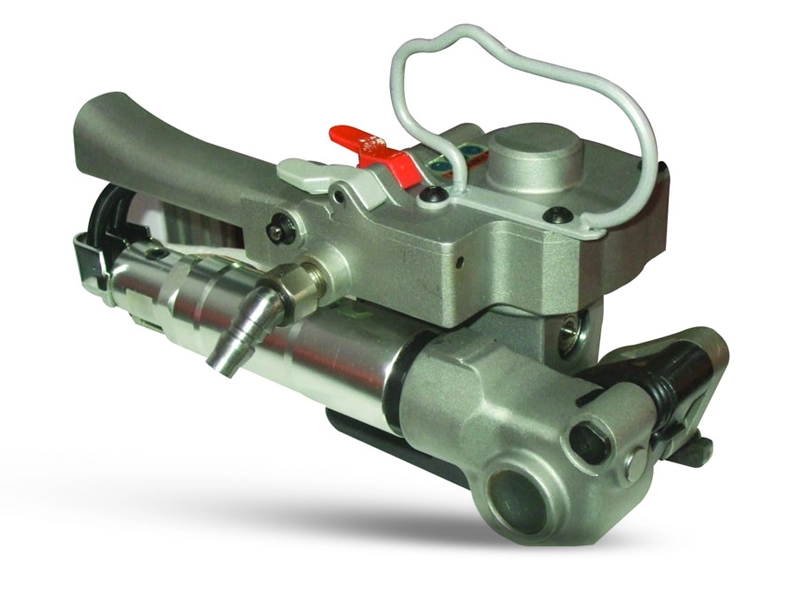

Unraveling the Manufacturing Process: The production of PP straps involves a meticulous process that transforms polypropylene into a versatile strapping material. This section provides an in-depth exploration of the manufacturing steps, from extrusion to stretching and heat sealing, unraveling the precision and technology behind crafting these essential carton packing straps.

The versatility of Polypropylene: Polypropylene stands out as a versatile material, and this section highlights the attributes that make it an ideal choice for PP straps. From its strength and flexibility to its resistance to weather and chemicals, discover why polypropylene is the material of choice for manufacturing straps that stand up to the demands of carton packing.

Eco-Friendly Strapping Solutions: The eco-conscious era demands sustainable choices. Explore how PP straps contribute to eco-friendly carton packaging. This part of the article delves into the recyclability of polypropylene and the environmental benefits of using PP straps, aligning with the global push towards sustainable manufacturing practices.

Crucial Role in Carton Packaging: PP straps are more than just securing materials; they are integral to the efficiency of carton packaging. Understand how these straps enhance the safety and stability of packed cartons, preventing damage during transit. Explore the various industries that rely on PP straps for secure and reliable carton packaging solutions.

Innovations in PP Strap Manufacturing: As technology evolves, so does the manufacturing of PP straps. This section explores recent innovations in the field, from advancements in strap design to eco-friendly initiatives. Stay informed about the latest trends shaping the landscape of PP strap manufacturing for carton packing.

Quality Control Measures: The precision in PP strap manufacturing is upheld by stringent quality control measures. This part of the article delves into the checks and balances implemented to ensure that each PP strap meets the highest standards, providing reliability and strength crucial for effective carton packaging.

Frequently Asked Questions (Toggle Style):

- How are PP straps manufactured for carton packing?

- The manufacturing process involves extrusion, stretching, and heat sealing. Check the article for a detailed exploration.

- Why is polypropylene chosen for PP strap manufacturing?

- Polypropylene’s strength, flexibility, and resistance to weather and chemicals make it an ideal material for PP straps.

- Are PP straps eco-friendly?

- Yes, PP straps are eco-friendly due to the recyclability of polypropylene, aligning with sustainable manufacturing practices.

- What role do PP straps play in carton packaging?

- PP straps enhance the safety and stability of packed cartons, preventing damage during transit.

- Which industries rely on PP straps for carton packing?

- Various industries, including logistics, manufacturing, and distribution, depend on PP straps for secure and reliable carton packaging.

- What recent innovations have occurred in PP strap manufacturing?

- The article explores advancements in strap design and eco-friendly initiatives shaping the landscape of PP strap manufacturing.

- How does polypropylene contribute to the versatility of PP straps?

- Polypropylene’s versatile characteristics contribute to the strength and flexibility of PP straps.

- Are PP straps suitable for international shipping?

- Yes, PP straps provide reliable carton packaging solutions, making them suitable for international shipping.

- What measures ensure the quality of PP straps during manufacturing?

- Stringent quality control measures are implemented to ensure each PP strap meets the highest standards for reliability and strength.

- Can PP straps be used with automated packaging systems?

- Yes, PP straps are compatible with automated packaging systems, enhancing efficiency in carton packing processes.