PP Woven Bags: The Strong and Durable Solution for Packaging

January 10, 2025

Get Ultimate Strength with Our Solvent-Based OPP Packing Tape – Perfect for Heavy-Duty Packaging

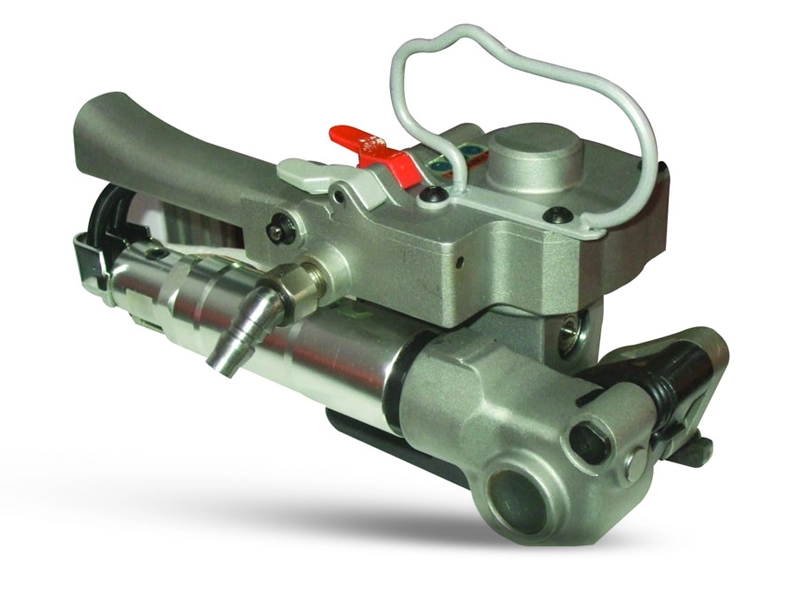

February 10, 2025Strapping machines have become an integral part of many industries, providing a quick and effective way to secure packages for shipping or storage. Whether you’re packaging fragile items, heavy loads, or anything in between, these machines make the process faster, more reliable, and incredibly secure. In this article, we’ll take a deep dive into what a strapping machine is, why it’s essential, and how it can improve your business’s packaging process.

What is a Strapping Machine?

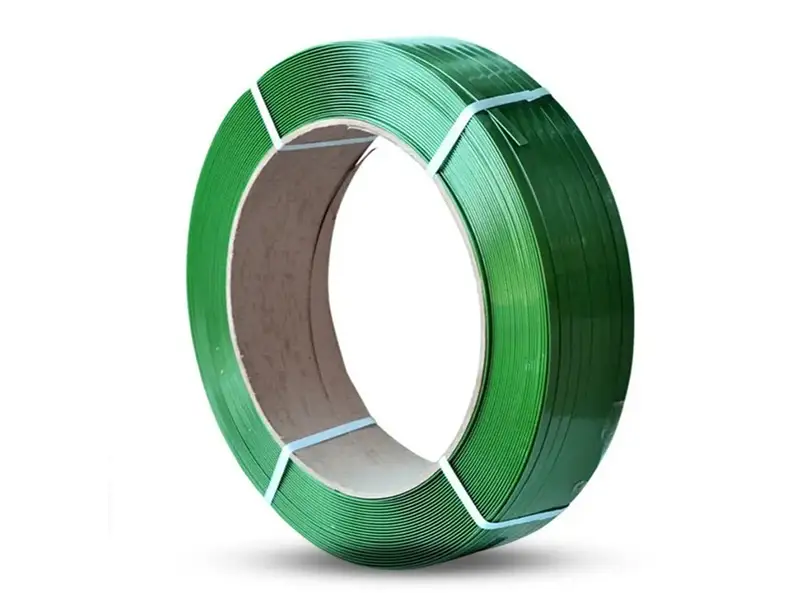

A strapping machine is a device used to apply straps to packages to keep them tightly bound. The strap—made from materials like polypropylene (PP), polyester (PET), or steel—ensures that packages remain secure during shipping or storage. This machine automates the process, saving time and ensuring consistency in every package. Whether you operate a small-scale business or manage a large logistics operation, a strapping machine is a tool that can provide enormous value.

Why Invest in a Strapping Machine?

Strapping machines offer numerous advantages:

- Speed: Manually strapping packages can be time-consuming. A machine automates the process, enabling you to package more goods in less time.

- Consistency: Human error is always a factor when packaging manually. Strapping machines ensure that every package is strapped securely and consistently.

- Cost-Efficiency: Over time, using a strapping machine can save money. You’ll reduce material waste and free up labor for other tasks.

- Versatility: Whether you’re securing small parcels or heavy shipments, strapping machines can be adjusted to handle a variety of packaging sizes.

Types of Strapping Machines

- Semi-Automatic Strapping Machines: These machines require manual feeding of the strap around the package, but they automate the tightening and sealing process. They are ideal for smaller operations.

- Automatic Strapping Machines: These fully automated machines handle the entire strapping process, from feeding the strap to cutting and sealing it. They are ideal for high-volume businesses that require speed and efficiency.

- Handheld Strapping Tools: These are portable strapping tools used when a stationary machine isn’t practical. They’re commonly used in industries like construction or agriculture.

Strapping Machine for Different Industries

Strapping machines are used in various sectors, including:

- E-commerce and Retail: To secure multiple packages for shipping.

- Manufacturing: For bundling large items, like appliances or machinery parts.

- Food & Beverage: Ensuring that products are tightly secured for transportation.

Each of these industries benefits from the reliability and efficiency that a strapping machine brings. The choice of strap material, such as PET Strap for Heavy Packaging or PP Strap for Packaging, depends on the specific application.

FAQs About Strapping Machines

- What materials can be used with a strapping machine?

Strapping machines can use materials like polypropylene (PP), polyester (PET), and steel, depending on the package requirements. - Can a strapping machine handle different package sizes?

Yes, most strapping machines are adjustable to accommodate various package dimensions. - How does a strapping machine save money in the long run?

By automating the process, it reduces labor costs and minimizes material waste. - Are there portable strapping machines?

Yes, handheld strapping tools are portable and ideal for on-site packaging needs. - How much maintenance does a strapping machine require?

Strapping machines are relatively low-maintenance, but regular cleaning and occasional parts replacement are recommended.