The Secret Weapon for Secure Shipments: Packing Tape Unveiled

October 22, 2024

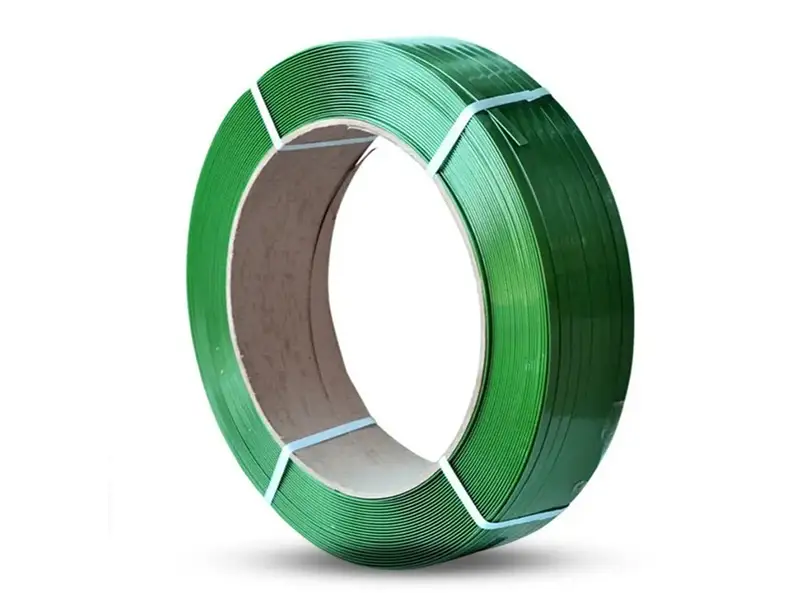

Plastic Bailing Hoops (Imported and 100% Pure Quality)

November 12, 2024In the world of packaging, securing items for transportation or storage is crucial. Stretch wrap film has proven to be a versatile and reliable solution for bundling, securing, and protecting products during transit. Whether it’s safeguarding items on pallets or grouping smaller packages together, stretch wrap film provides an effective barrier against damage, dust, and environmental elements. This article explores the benefits, types, and various applications of stretch wrap film, explaining why it is a key component in packaging.

What is Stretch Wrap Film?

Stretch wrap film is a plastic film made from linear low-density polyethylene (LLDPE) and is highly stretchable. Its main purpose is to hold items tightly together on a pallet, providing stability and protection. By applying tension, the film adheres to itself, creating a secure seal that prevents the contents from shifting during movement.

Unlike shrink wrap, which requires heat to conform to the shape of the item, stretch wrap only requires manual or machine tension to keep items in place. This makes it a more efficient and cost-effective packaging material for large-scale operations.

Types of Stretch Wrap Film

- Hand Stretch Film

Hand stretch wrap is designed for manual application using a handheld dispenser. It is best suited for smaller operations or when the volume of wrapping is low. It offers flexibility and is easy to apply without specialized machinery. - Machine Stretch Film

Machine stretch film is used in automated or semi-automated wrapping systems for high-volume packaging operations. This type of film is applied more consistently and tightly, offering better load containment and stability, which is ideal for pallet wrapping in warehouses or distribution centers. - Blown Stretch Film

Blown stretch film is manufactured through a blown extrusion process and is known for its strength and resistance to punctures. This makes it ideal for securing irregular or sharp-edged items that need extra protection during transit. - Cast Stretch Film

Cast stretch film is created through a cast extrusion process, making it clearer, quieter, and easier to unwind. This type of stretch wrap is typically used when high clarity is required to identify barcodes or other labels on the items being wrapped. - Pre-Stretched Film

Pre-stretched film has been mechanically stretched during the manufacturing process. This reduces the amount of physical effort needed during application and minimizes the film’s use, making it a cost-effective and environmentally friendly option.

Benefits of Stretch Wrap Film

- Protection and Security

Stretch wrap film provides excellent protection against dust, dirt, and moisture. It also prevents tampering and keeps items secure during transportation, reducing the risk of damage or theft. - Stability

One of the main benefits of stretch wrap film is its ability to stabilize loads on pallets. It ensures that items remain securely bundled together, reducing the likelihood of shifting, tipping, or falling during shipping. - Cost-Effective

Stretch wrap film is an affordable solution for businesses looking to secure products without investing in expensive packaging materials. The film’s ability to stretch and cover large areas with minimal material makes it a highly efficient option. - Flexibility

Stretch wrap film can be used for a wide variety of applications. From wrapping furniture to securing industrial products on pallets, it offers flexibility across different industries. - Environmentally Friendly Options

Many manufacturers offer stretch wrap film made from recyclable materials. Additionally, pre-stretched films reduce material usage, contributing to more sustainable packaging practices.

Industries That Use Stretch Wrap Film

- Logistics and Warehousing

Stretch wrap film is essential in logistics and warehousing, where it stabilizes loads on pallets, ensuring safe transport of goods over long distances. - Retail and E-commerce

Retailers and e-commerce businesses use stretch wrap to bundle products and ensure they are protected during shipping, ensuring they reach customers intact. - Food and Beverage

Stretch wrap is commonly used to wrap pallets of food and beverage products, offering protection from contaminants and maintaining product integrity. - Manufacturing

In the manufacturing sector, stretch wrap is used to secure large equipment, machinery, or heavy products for safe handling and shipping.

How to Choose the Right Stretch Wrap Film

Choosing the right type of stretch wrap film depends on several factors, including the weight, shape, and fragility of the items being wrapped. Consider the following:

- Type of Load: For lighter loads, hand stretch film is sufficient. Heavier or irregular-shaped loads may require machine-applied or blown stretch film for added security.

- Environmental Conditions: If products will be exposed to sunlight or extreme temperatures, it’s essential to choose UV-resistant or temperature-tolerant stretch film.

- Clarity Needs: For applications requiring product identification through barcodes or labels, cast stretch film is the best option due to its clarity.

FAQs About Stretch Wrap Film

- What is the main difference between stretch wrap and shrink wrap?

Stretch wrap uses tension to adhere to items and hold them together, while shrink wrap requires heat to shrink around the product and conform to its shape. - Is stretch wrap film recyclable?

Yes, many types of stretch wrap films are recyclable, especially those made from polyethylene. It’s important to check the specific type of film for recycling guidelines. - Can stretch wrap be reused?

While stretch wrap is typically a single-use product, it can sometimes be reused if it remains intact after the initial application. However, for maximum security, it’s recommended to use fresh wrap each time. - How much stretch wrap should I use per pallet?

The amount of stretch wrap required depends on the size, weight, and type of items on the pallet. For standard pallets, approximately 3-5 layers of wrap are typically used. - Can stretch wrap film be used for items other than pallets?

Yes, stretch wrap is versatile and can be used to bundle smaller items, furniture, or even individual packages for added protection.